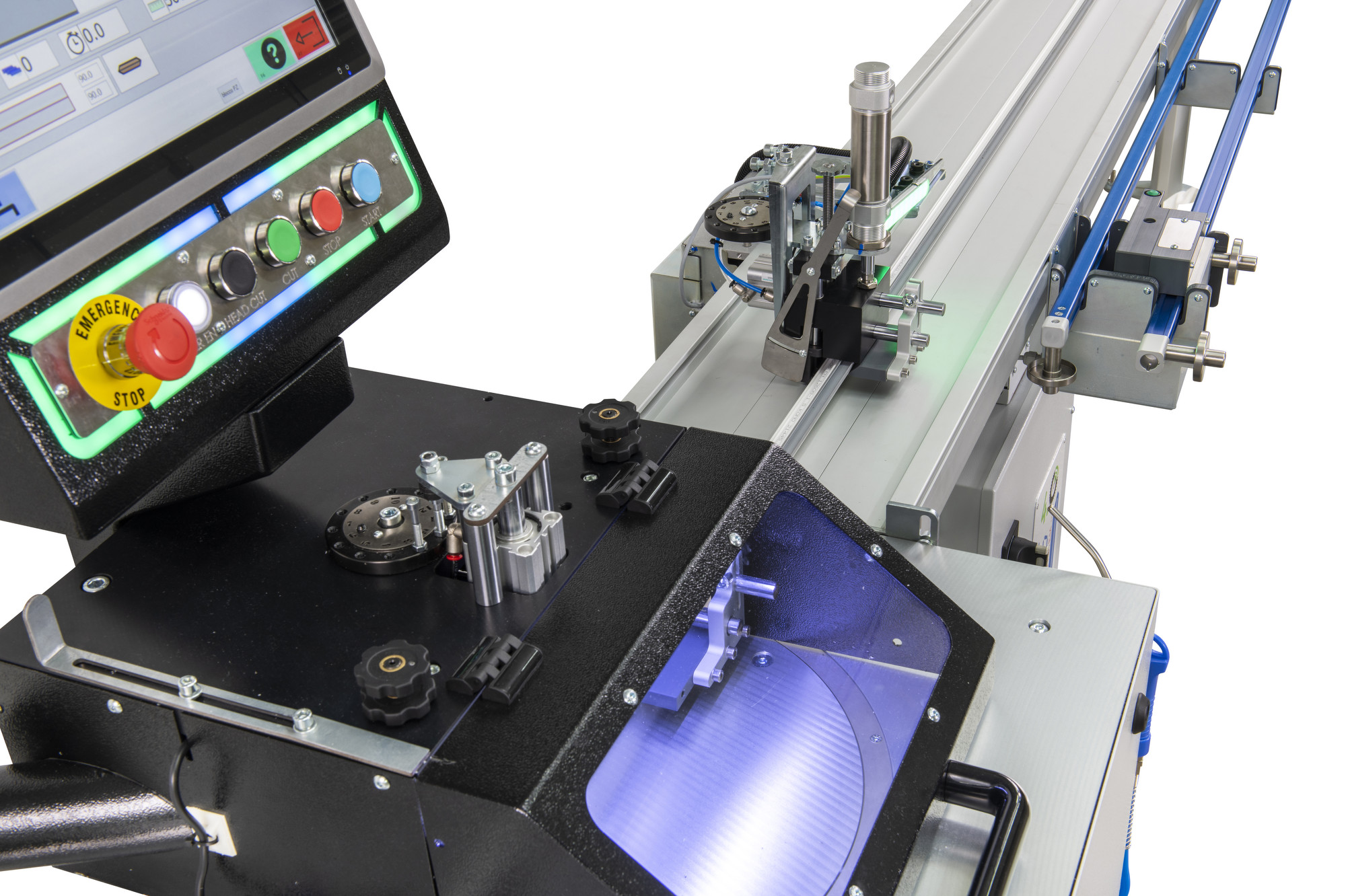

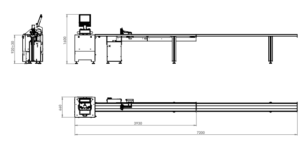

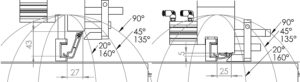

DigiBS IG 4.0 – Troncatrice per fermavetri in PVC con angolo di taglio variabile (20°-160°) integrata a rulliera elettronica con pinza di carico automatica.

Nella versione DigiBS IG 4.0 il fermo battuta si trasforma in una pinza di carico di nuova progettazione.

Lo sviluppo di questa pinza di carico vede concentrata tutta l’esperienza acquisita con il sistema di blocco del profilo privo di sagome della DigiBS4.0.

Questo nuovo sistema è stato pensato per riuscire a coprire la più vasta gamma possibile di fermavetro senza dover ricorrere a sagome specifiche, tenendo saldamente il profilo nella giusta posizione ed alimentando l’unità di taglio dell’esatta lunghezza di barra necessaria.

All’operatore rimane il compito di caricare una nuova barra, effettuare l’intestatura e scaricare i pezzi lavorati.

Sulla pinza è montata inoltre una fotocellula, grazie a questa la DigiBS4.0-IG riconosce la fine della barra di alimentazione e informa l’operatore nel caso non ci sia sufficiente materiale per proseguire con la lavorazione.

Operatività

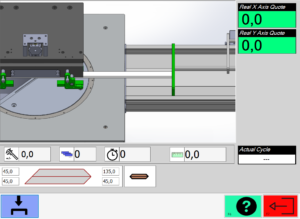

- Inserimento manuale delle misure direttamente da interfaccia

- Caricamento della lista di taglio da via memoria USB o Ethernet / Wi-Fi

- Ricezione via radio delle misure dal calibro elettronico DigiBAR e creazione lista di taglio

È possibile aggiungere, cancellare e modificare qualsiasi riga in qualsiasi momento, saltare da una riga all’altra, gestire il taglio di intestatura.

L’integrazione con il calibro elettronico DigiBAR 4.0 è il modo più comune per lavorare con la troncatrice DigiBS 4.0 IG. L’unità di controllo della DigiBS integra un’avanzata interfaccia radio che è in grado di creare e gestire una robusta rete radio in officina.

Tutti i prodotti della famiglia DigiFAMILY sono in grado di utilizzare questa rete per scambiare informazioni.

L’elevata integrazione rende lavorare con DigiBS 4.0 IG e DigiBAR4.0 molto semplice, una lista di taglio è generata in tempo reale sullo schermo durante il ciclo di misura.

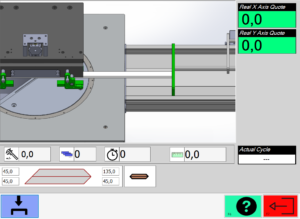

Lo schermo touch screen a colori contiene tutte le informazioni necessarie all’operatore durante il ciclo di lavoro, le aree colorate indicano in maniera chiara e immediata lo stato della macchina.

Software

| ELETTRONICA |

| HMI |

PC Indust. 15” Touch Screen SSD Win 10 IoT |

| Interfaccia radio ( coll. DigiBAR) |

Integrata |

| USB per tastiera/mouse esterni e flash drive |

Integrata |

| WI-FI |

Integrata |

| Ethernet |

Integrata |

UNITÀ DI CONTROLLO / CONNETTIVITÀ

DigiBS4.0-IG è comandata da un PC Industriale 15” Touch Screen collegato a schede PLC.

Il sistema operativo Industriale Windows 10 IoT unisce la semplicità dell’ambiente Windows con la stabilità dei sistemi destinati agli ambienti produttivi.

Il software sviluppato per la DigiBS4.0-IG è in grado di riconoscere il ciclo di lavoro riportato in lista (che sia importato da una risorsa di rete, da una memoria USB o compilato in macchina dalle misure ricevute da un dispositivo DigiBAR) e gestire automaticamente l’intestatura del profilo quando necessario.

Questo sistema riesce così ad escludere la maggior parte degli errori di produzione causati dall’operatore, come un errato posizionamento del profilo nell’unità di taglio o contro la battuta del fermo di misura assicurando una ripetibilità e una precisione che solo una macchina a controllo numerico può garantire.

In caso di necessità la modalità manuale della DigiBS4.0-IG consente la lavorazione del profilo come sulla macchina standard, invertendo il flusso di lavoro e usando il piccolo fermo di battuta presente sulla pinza.

DigiBS4.0-IG è una MACCHINA CONNESSA. Le configurazioni, i dati di officina, i parametri e i dati di produzione vengono costantemente salvati sulla nuova piattaforma DigiCLOUD.

Questo servizio permette di limitare al massimo i tempi di ripartenza in caso di problemi Hardware software.

Il programma macchina è dotato di help contestuale in linea che informa l’operatore sui comandi della macchina e, in caso di avarie, offre un servizio di troubleshooting guidando l’operatore alla soluzione del problema con foto e schemi elettrici/pneumatici direttamente sullo schermo.

Il servizio DigiINDUSTRY 4.0 (opzionale) permette la consultazione, esportazione dei dati di produzione, dello stato macchina (conformemente ai protocolli Industry 4.0).