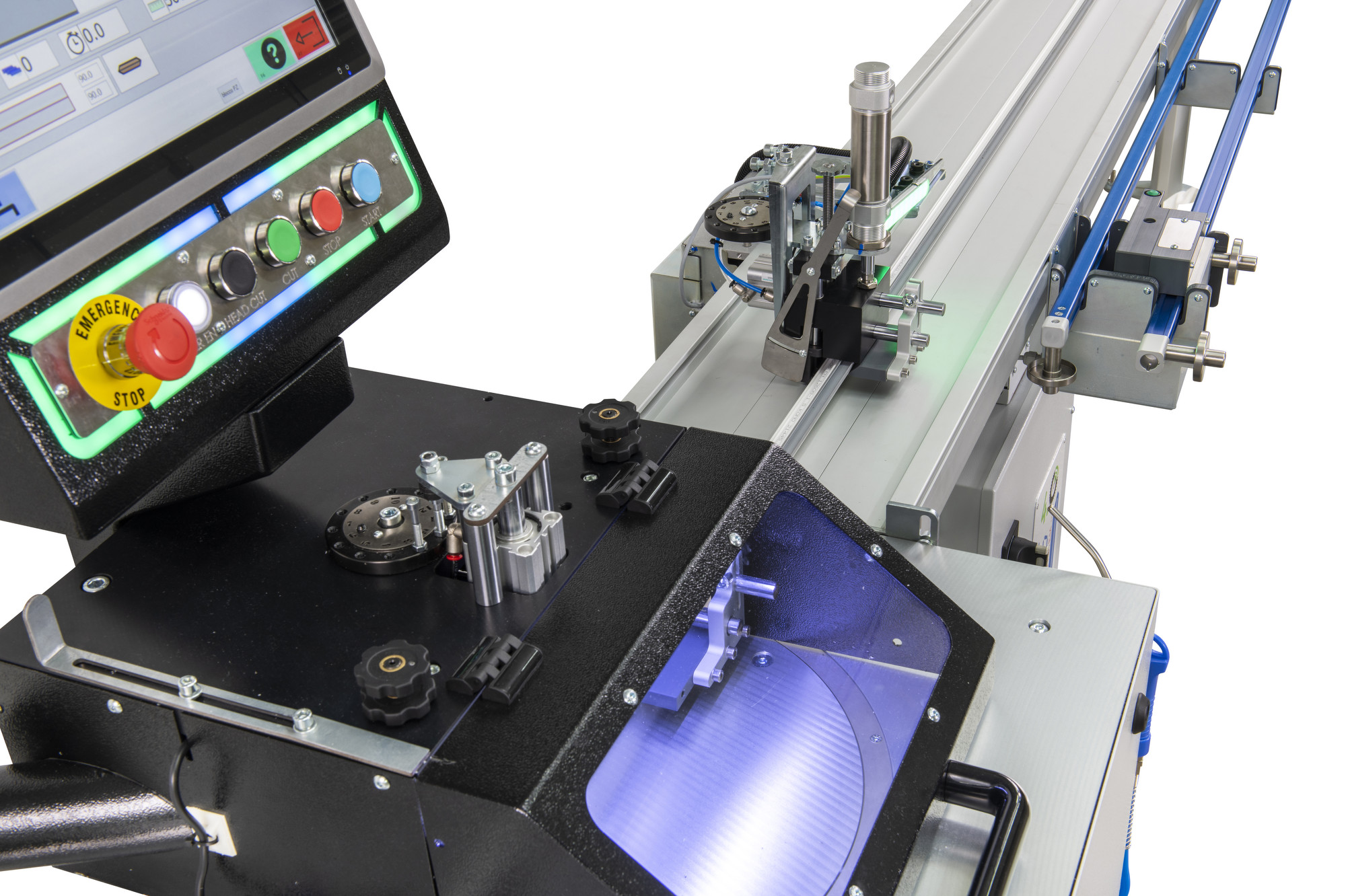

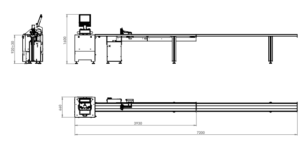

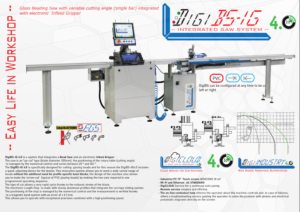

In the DigiBS 4.0-IG version the length stop is transformed into an infeed gripper.

This system is designed to keep the profile clamped in the correct position and feed the cutting unit automatically with the exact amount of bars needed.

The operator needs only to load a new bar, perform the first cut and unload the worked pieces.

A photocell installed on the clamping unit also activates the machine when the bar is too short to perform the cutting process and informs the operator to prepare and load a new one.

Cutting list creation

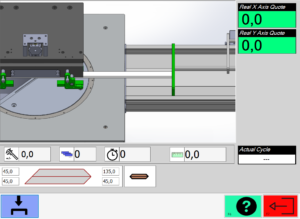

- Manual entering of data from touch screen

- Loading files from USB memory, Ethernet or Wi-Fi (.txt)

- Radio reception of measurements from the DigiBAR electronic gauge and automatic creation of list

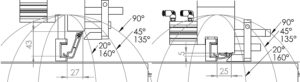

It is possible to add, delete and edit any line at any time, selecting the line directly from the touch screen. If needed, the machine is able to manage the head cut of any initial cutting cycle.

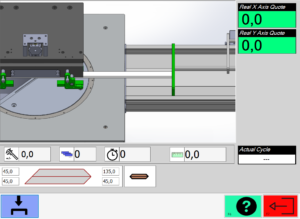

The carriage fence moves automatically away from the saw after the cutting operation to facilitate cut piece removal. Moreover, the color touch screen contains all the information the operator needs during the work cycle, the colored areas clearly and immediately indicate the status of the machine.

The integration with the DigiBAR 4.0 electronic gauge is the most common and easiest way to work with the DigiBS bead saw: a cutting list will be automatically generated in real time during the measurement cycle.

The DigiBS IG control unit integrates an advanced radio interface that is able to create and manage a robust radio network in the whole workshop.

All the products of the DigiFAMILY family are able to use this network to exchange information.

Electronics and Software

| ELECTRONICS |

| HMI |

Indust. PC 15” Touch Screen SSD Win 10 IoT |

| Radio Interface (DigiBAR commun.) |

Integrated |

| USB port for Keyboard Memory |

Integrated |

| WI-FI |

Integrated |

| Ethernet |

Integrated |

DigiBS IG 4.0 is controlled by a 15” Touch Screen Industrial PC connected to PLC cards.

The Windows 10 IoT Industrial operating system combines the simplicity of the Windows environment with the stability of systems intended for production environments.

The software is designed to recognize the working cycle directly from the list, either imported from a net source, from an USB or a DigiBAR, and it automatically prepares the first cut when it changes.

In this way, the system excludes most of the operator induced errors, like mispositioning the profile in the clamping device, ensuring precision and repeatability like only a computer controlled machine can do.

For special necessities, like reworking a few pieces or doing some tests, the machine can work as a standard DigiBS in manual mode, the working flow is reversed and a small fence is installed on the clamping system.

DigiBS IG 4.0 is a CONNECTED MACHINE.

Configurations, workshop data, parameters and production data are constantly saved on the new DigiCLOUD platform. This service allows you to minimize restart times in the event of hardware and software problems.

The operating system is equipped with an on-line contextual help that informs the operator about the machine’s commands and, in case of breakdowns, offers a problem-solving service guiding the operator to solve the problem with photos and electrical / pneumatic diagrams directly on the screen.

DigiINDUSTRY 4.0 (optional) is an additional service that allows production data analysis, to monitor the status of the machine and the working processes, in compliance with the Industry 4.0 procedures.