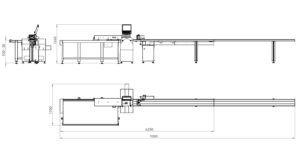

DigX is “reversible”, with the possibility of having the outfeed table both on the left or on the right side of the machine. Even after installation, sliding the electrical panel from one side to the other, the length stop can be easily placed on the left or the right side of the bead saw.

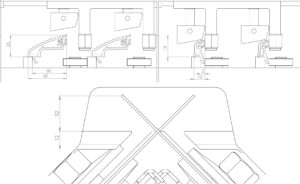

An exclusive guide and support system for the glazing bead facilitates the profile loading while the precise positioning and clamping are operated by the pneumatic piston glass simulator (12 selectable settings for the four pneumatic clamps), to obtain a rapid working cycle.

The EGS Electronic Glass Simulator is an additional option, which allows you to set an “infinite” number of glazing beads.

DigiX can count on an efficient chip and waste evacuation system.

The electronic Length Stop is made with sturdy aluminum profiles that integrate the carriage sliding system. The positioning of the stop is managed by the numerical control and the measurement is verified thanks to a magnetic band system with an error of ± 0.1 mm.

This allows for exceptional precision combined with a high positioning speed.

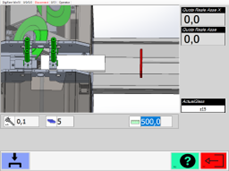

Cutting list creation

- Manual entering of data from touch screen

- Loading files from USB memory, Ethernet or Wi-Fi (.txt)

- Radio reception of measurements from the DigiBAR electronic gauge and automatic creation of list

It is possible to add, delete and edit any line at any time, selecting the line directly from the touch screen. If needed, the machine is able to manage the head cut of any initial cutting cycle.

The carriage fence moves automatically away from the saw after the cutting operation to facilitate cut piece removal. Moreover, the color touch screen contains all the information the operator needs during the work cycle, the colored areas clearly and immediately indicate the status of the machine.

The integration with the DigiBAR 4.0 electronic gauge is the most common and easiest way to work with the DigiX bead saw: a cutting list will be automatically generated in real time during the measurement cycle.

The DigiX control unit integrates an advanced radio interface that is able to create and manage a robust radio network in the whole workshop.

All the products of the DigiFAMILY family are able to use this network to exchange information.